Heat Exchanger For Paddy Dryer Heater

Price 80000 INR/ Unit

Heat Exchanger For Paddy Dryer Heater Specification

- Type

- Heat Exchanger

- Material

- M.S, S.S

- Voltage

- 415 Volt (v)

- Power Source

- Electricity

Heat Exchanger For Paddy Dryer Heater Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA)

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Heat Exchanger For Paddy Dryer Heater

Heat Exchanger for Paddy Dryer Heater offered by our company, is designed and manufactured by making use of optimum grade of raw materials and high technology. This heater uses electricity to move heat from a cool space to a warm space, making the cool space cooler and the warm space warmer. Heat Exchanger for Paddy Dryer Heater can be beneficial in reducing energy usage in a number of applications. This is very economical to use.

Specifications

| Usage/Application | Hydraulic and Industrial Process |

| Type | Heater |

| Material | Mild Steel |

| Brand | Mark |

| Surface Finish | Polished |

| Heater Material | M.S, S.S |

Reliable Heating for Paddy Dryers

This heat exchanger delivers optimal thermal performance, specifically designed for paddy dryer heating applications. Its engineered construction ensures even heat distribution, which is critical for preserving grain quality during the drying process.

Durable Construction Options

Choose from premium Mild Steel (M.S) or Stainless Steel (S.S) materials to match your durability and corrosion resistance needs. Both variants are designed for longevity and efficient heat transfer, making them suitable for continuous industrial use.

Proudly Made in India

As a reputable manufacturer and supplier based in India, we uphold stringent quality standards throughout production, ensuring every unit delivers reliability and meets the demands of modern rice processing facilities.

FAQ's of Heat Exchanger For Paddy Dryer Heater:

Q: How does the heat exchanger for a paddy dryer heater function?

A: The heat exchanger operates by transferring heat generated from an electric source (415 Volt) to the air that circulates within the paddy dryer. This process ensures efficient and controlled drying of rice grains while maintaining consistent temperature levels.Q: What types of materials are available for the heat exchanger, and why do they matter?

A: You can select from Mild Steel (M.S) and Stainless Steel (S.S) for the heat exchanger body. Stainless steel offers excellent corrosion resistance and is ideal for humid environments, while mild steel provides cost-effective durability for most standard operations.Q: When should a heat exchanger be installed or replaced in a paddy dryer system?

A: Install a heat exchanger during initial setup or when upgrading to improve drying efficiency. Replacement is recommended if your current unit shows degradation, frequent breakdowns, or diminished heat transfer performance.Q: Where are these heat exchangers manufactured and supplied?

A: Our heat exchangers are manufactured and supplied from India, where we adhere to high industrial standards and deliver across the country to paddy processing facilities.Q: What is the process of integrating this heat exchanger into my existing drying system?

A: Integration involves connecting the heat exchanger to your paddy dryer's air circulation and electrical system (415 Volt supply). Our team provides guidance and support to ensure seamless installation and optimum performance.Q: What are the usage benefits of this heat exchanger in paddy drying applications?

A: Using this heat exchanger enhances drying efficiency, shortens processing time, and helps preserve paddy grain quality. Its robust design ensures reliable, uninterrupted operation, making it highly beneficial for high-volume rice processing plants.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Dryer Heater Category

Industrial Tubular Heater

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other, Industrial Tubular Heater

Power Source : Electric

Material : Other, Mild Steel

Voltage : 220 Volt (v)

Heat Exchanger for Dryer Heater

Type : Other, Shell & Tube Heat Exchanger

Power Source : Electric

Material : Stainless Steel

Voltage : 220V

Heat Exchanger For Salt Dryer

Price 85000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other

Power Source : Electricity

Material : Other

Voltage : 415 Volt (v)

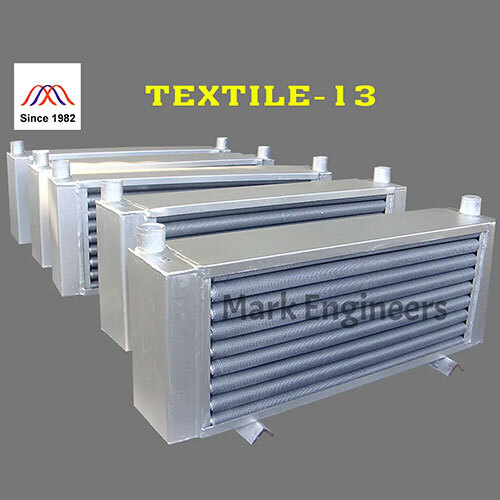

Textile Radiator Dryer Heater

Price 65000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Other

Power Source : Electricity

Material : Stainless Steel

Voltage : 415 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese